How to Match Your Bakery Mixer to Dough Type and Volume

Contents

1.Introduction: Why the Right Mixers Matters

2.Overview of Commercial Mixer Types

3.Matching Mixer to Dough Type

4.Batch Volumn and Production Scale

5.Additional Considerations When Choosing a Mixer

6.Choosing a Reliable Manufacturer

1. Introduction: Why the Right Mixer Matters

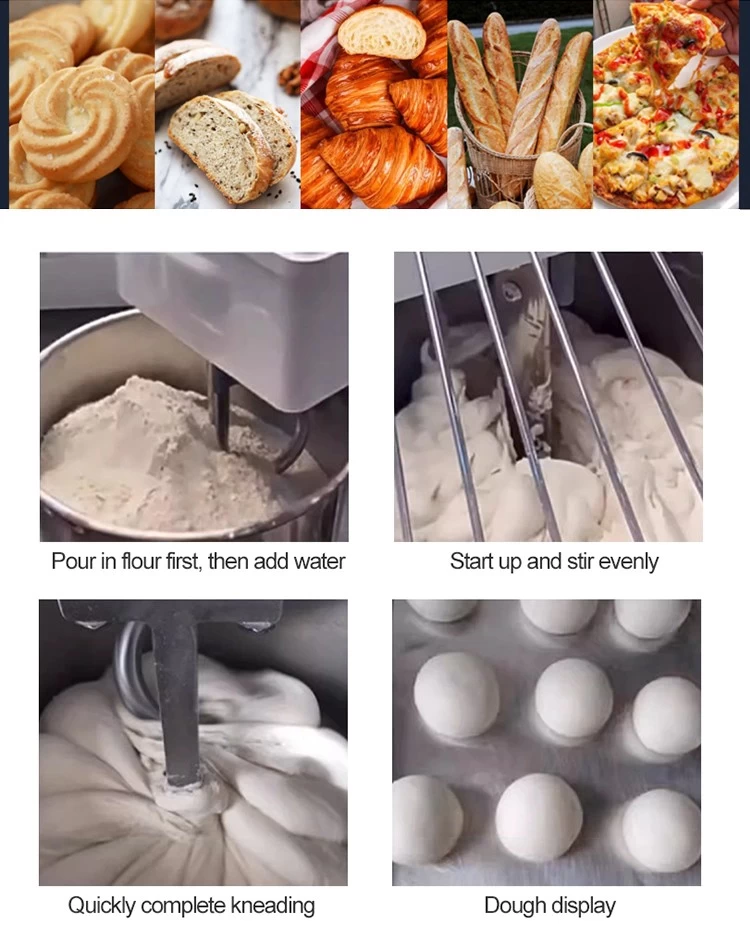

In commercial baking, consistency, efficiency, and product quality begin with the right mixing process. Choosing a suitable dough mixer isn’t just about power or price—it’s about understanding your production volume, dough characteristics, and product diversity. Whether you're mixing stiff pizza dough or delicate cake batter, using the wrong type of mixer can affect dough development, texture, and even equipment lifespan. This guide by Tsingbuy China commercial dough mixer supplier breaks down the key differences between spiral and planetary mixers and helps you identify the best match for your bakery’s needs—by dough type, batch size, and production goals.

2. Overview of Commercial Mixer Types

Choosing the right commercial mixer is essential for maximizing efficiency and achieving consistent product quality in a professional bakery. With various dough types requiring different mixing actions and capacities, understanding the differences between spiral and planetary mixers can help you select the ideal equipment for your production needs.

● Spiral vs. Planetary Mixers: Key Differences

Spiral Mixers are specifically designed for heavy, low-hydration doughs such as pizza, bagels, and artisan breads. Their spiral-shaped agitator and rotating bowl work together to gently develop gluten structure while minimizing heat buildup—critical for yeast-based doughs. Spiral mixers typically have higher capacities and are better suited for large batches of the same type of dough.

Planetary Mixers, on the other hand, feature a stationary bowl and an agitator that moves in an orbital (planetary) motion. This versatile design accommodates a wide range of mixing attachments—such as a paddle, hook, or whisk—making it ideal for preparing various batters and doughs including cookies, cakes, soft bread, icing, and pastry cream. Planetary mixers are preferred in bakeries that require flexibility and smaller batch sizes.

● Spiral Mixers

- Design: A spiral hook rotates on its own axis while the bowl simultaneously rotates in the opposite direction.

- Function: Mimics hand-kneading, ideal for developing gluten gently.

- Typical Use: Designed specifically for yeast-based dough with low hydration.

- Capacity: Typically available in medium to large capacities (20–200L+).

- Advantages:

- Uniform mixing with minimal heat generation

- Faster kneading time for heavy doughs

- Strong gluten structure

- Ideal for large-scale production of one dough type

● Planetary Mixers

- Design: A single agitator moves in a planetary motion (like the earth rotating the sun) while the bowl remains stationary.

- Function: Versatile tool with interchangeable attachments.

- Typical Use: Best for a wide range of mixing tasks—from batters to creams and softer doughs.

- Capacity: Typically available from small countertop units to 100L+ floor models.

- Advantages:

- Multipurpose: dough, batter, creams, meringues

- Tool versatility (hook, paddle, whisk)

- Excellent for bakeries with diverse product lines

3. Matching Mixer to Dough Type

Best Mixer Choices for Common Bakery Products

Pizza Dough / Bagel Dough / Artisan Bread:

➤ Best choice: Spiral Mixer

High-gluten, low-hydration doughs benefit from the gentle yet powerful kneading of spiral mixers, which ensure strong gluten development and excellent fermentation.

Soft Bread (e.g., sandwich loaves, dinner rolls):

➤ Best choice: Spiral Mixer or Planetary Mixer (depending on volume)

Spiral mixers are ideal for large-scale production, while a planetary mixer can work well for smaller operations.

Cookies / Shortbread Dough:

➤ Best choice: Planetary Mixer with Paddle Attachment

Planetary mixers provide the right creaming and blending action for cookie doughs with butter, sugar, and inclusions like chocolate chips or nuts.

Cake Batter / Muffins / Whipped Fillings:

➤ Best choice: Planetary Mixer with Whisk or Paddle

The planetary mixer's ability to switch tools makes it perfect for delicate batters and aerated mixes that require controlled mixing.

4. Batch Volumn and Production Scale

● Small Bakeries & Pastry Shops

- Often produce a variety of products in smaller batches

- Best choice: Planetary mixers (10–40L models)

- Benefits:

- Versatile for a wide range of applications

- Economical for limited production space

● Medium-Scale Commercial Bakeries

- Require consistency in daily dough production

- Best choice: Combination of spiral mixer (for bread) and planetary mixer (for cakes, fillings)

- Tip: Consider investing in a planetary mixer with programmable speed control.

● Large-Scale Industrial Bakeries or Food Plants

- High-volume dough mixing with integration into automatic production lines

- Best choice: High-capacity spiral mixers with programmable controls and dough temperature monitoring

- Add-on Features:

- Hydraulic bowl lifting

- Tilting systems

- Safety covers and emergency shut-off

5. Additional Considerations When Choosing a Mixer

- Dough Hydration Level: Heavier, drier doughs require more torque and robust mixing arms.

- Product Diversity: If producing varied items daily, planetary mixers offer unmatched versatility.

- Space and Layout: Floor space, power supply, and ventilation must be considered for large mixers.

- Automation Compatibility: Spiral mixers with automated dough handling suit continuous production systems.

- Maintenance and Cleaning: Look for easy-access parts and durable stainless steel construction.

6. Choosing a Reliable Manufacturer: Why Bakesphere?

When investing in bakery equipment, durability and support are just as crucial as functionality. Bakesphere, a professional bakery machine manufacturer in China, offers a wide range of spiral and planetary mixers engineered for commercial kitchens and food factories. Known for their robust construction, customizable features, and dependable after-sales service, Bakesphere mixers help bakeries worldwide achieve consistent mixing performance—batch after batch.

● What Sets Bakesphere Apart?

- Customizable Features: Mixers can be tailored to your dough type, batch size, and even integrated into automated systems.

- Built for Durability: Reinforced frames, premium-grade motors, and food-grade stainless steel ensure long-term reliability.

- Global Service Network: Bakesphere supports commercial kitchens, bakeries, and food factories across multiple continents.

- ODM & OEM Capabilities: From standard models to tailor-made solutions, Bakesphere partners with clients to develop mixers that match their unique production needs.

Conclusion: The right mixer is more than a tool—it’s the backbone of your bakery’s production quality. By aligning your choice of mixer with your specific dough types, daily volume, and production setup, you ensure better results and long-term efficiency. Spiral mixers excel at bread and pizza dough, while planetary mixers deliver unmatched versatility for cake batters, cookies, and creams. Whether you’re expanding your current bakery or launching a new production line, Bakesphere baking equipment factory in China provides high-performance mixers backed by expert engineering and industry insight. Let your mixer match your craft—perfectly.