How to Choose the Right Commercial Oven for Your Bakery

Contents:

1. Why Choosing the Right Oven matters?

2. Understand Your Baking Needs First

3. Overview of Main Commercial Oven Types

4. Gas vs.Electric Ovens: Which One is Right for You?

5. Key Considerations When Choosing an Oven

6. Matching the Oven to Your Bakery Type

7. Why Choose Bakesphere Ovens

1. Why Choosing the Right Oven Matters?

In any commercial bakery, the oven is more than just a machine — it’s the heart of production. Whether you're crafting crusty artisan loaves, delicate pastries, or high-volume batches of sandwich bread, the performance of your oven directly influences the quality, consistency, and efficiency of your output. Selecting the right oven isn’t a one-size-fits-all decision; it depends on your product range, production capacity, and operational setup.

A well-matched oven not only improves baking results but also optimizes workflow, reduces energy consumption, and enhances long-term profitability. With so many models and configurations available, it’s crucial to understand the differences before investing. At Bakesphere, we specialize in supplying a full range of commercial bakery ovens — including rotary ovens, deck ovens, convection ovens, and pizza ovens — to help professional bakers and food factories achieve peak performance. This guide will walk you through the essential factors to consider when choosing the best oven for your bakery’s needs.

2. Understand Your Baking Needs First

Before diving into oven specifications and technical features, the most important step is to clearly define what you need from your oven. Every bakery operates differently — and the right oven for one business may not suit another.

Start by identifying the type of products you primarily bake. Are you focused on soft sandwich loaves, crusty artisan breads, delicate pastries, or high-temperature pizzas? Each product requires a specific baking environment in terms of heat distribution, humidity, and temperature control.

Next, consider your production volume. A small café or boutique bakery might prioritize space-saving equipment with flexible functionality, while a commercial food factory demands high-capacity ovens built for continuous, large-scale output.

Don’t forget to evaluate your available space and kitchen layout. A rotary oven, for example, may require more floor area than a deck oven but offers greater efficiency for bulk baking. In contrast, stackable deck ovens can save space while still offering multi-level baking.

Understanding these core needs will help you narrow down your options and choose a commercial oven that supports both your current output and future growth — whether you’re scaling up production or streamlining operations.

3. Overview of Main Commercial Oven Types

Choosing the right commercial oven starts with understanding the key differences between the main types. Each oven is engineered to meet specific baking demands, and selecting the correct one can significantly impact both product quality and operational efficiency. Below is an overview of the commercial ovens Bakesphere offers, each designed to serve different bakery production needs:

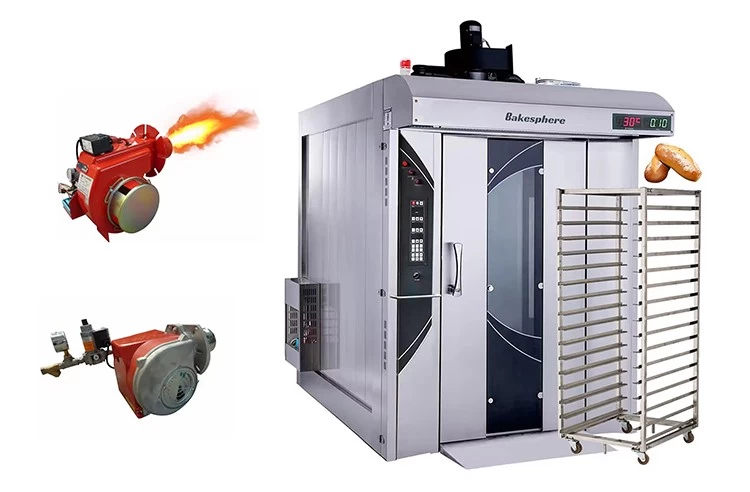

● Rotary Rack Oven

The rotary oven is ideal for high-volume production. Its rotating rack system ensures even heat circulation, delivering consistent results across every tray. It’s particularly suitable for baking bread, rolls, muffins, cookies, and other products in large quantities. Rotary ovens are often used in food factories and large bakeries where efficiency and uniformity are key.

● Deck Oven

Deck ovens are favored by artisan bakers for their ability to reproduce traditional baking methods. With multiple decks and stone or metal baking surfaces, they offer precise temperature control and excellent bottom heat — perfect for crusty breads, baguettes, pizzas, and pastries. Deck ovens also allow for independent temperature regulation per deck, offering flexibility for diverse baking needs.

● Convection Oven

Compact, versatile, and efficient, convection ovens use a fan to circulate hot air, resulting in quick and even baking. They are commonly used in cafés, pastry shops, and bakeries producing items like cookies, croissants, and small cakes. Convection ovens are an excellent choice for operations with limited space but high demands for speed and consistency.

● Pizza Oven

Designed specifically for pizza baking, these ovens reach very high temperatures to deliver the crisp base and bubbling cheese that define a great pizza. Whether gas- or electric-powered, Bakesphere’s commercial pizza ovens are available in single or multi-deck formats to suit restaurants and pizzerias with different output needs.

Each oven type comes with its own strengths, and the best fit depends on your product type, desired texture, and production scale. In the next section, we’ll compare fuel types — gas vs. electric — and how they affect oven performance.

4. Gas vs. Electric Ovens: Which One Is Right for You?

One of the most important decisions when selecting a commercial oven is choosing between gas and electric power. Each option has its own advantages depending on your bakery’s energy setup, local utility costs, and baking requirements.

● Gas Ovens

Gas ovens (using either natural gas or LPG) are often preferred in high-volume commercial settings due to their faster heat-up times and lower long-term operating costs. They typically provide strong, steady bottom heat — ideal for bread and pizza baking. However, installation requires a reliable gas connection and proper ventilation. Maintenance may also be more complex compared to electric models.

Pros:

- Lower energy cost over time

- Faster preheating

- Powerful heat — good for bread and pizza

- Ideal for industrial-scale baking

Considerations:

- Needs a stable gas supply

- Requires ventilation system

- May need more frequent maintenance

● Electric Ovens

Electric ovens are often chosen for their ease of installation, precise temperature control, and cleaner operation. They are well-suited for environments where gas access is limited or where smaller-scale baking is the focus. Electric ovens tend to have more even heat distribution, which is beneficial for delicate pastries and baked goods requiring consistent results.

Pros:

- Easy installation, especially in urban or indoor spaces

- Consistent heat distribution

- Easier to clean and maintain

- Precise temperature control

Considerations:

- Higher electricity costs over time

- May take longer to reach target temperature

- Might not provide strong bottom heat for artisan breads or pizzas

Ultimately, your choice should align with your production needs, budget, and site conditions. Bakesphere offers both gas and electric models across our oven range, giving you the flexibility to choose what works best for your bakery.

5. Key Considerations When Choosing an Oven

Selecting the right commercial oven involves more than just picking a type or power source. To ensure your investment supports both product quality and long-term efficiency, it's important to assess several critical factors:

● Capacity and Tray Size

Consider the number of trays you need to bake per batch, and make sure the oven accommodates standard tray sizes (e.g., 400×600 mm). For high-output operations, a rotary oven with 32 or more tray capacity may be ideal. For smaller shops, a multi-deck oven or convection oven may be sufficient.

● Temperature Range and Control

Different baked goods require different baking temperatures. Ensure the oven provides the temperature range and precision controls you need, especially if you bake a wide variety of products. Independent deck controls are crucial in multi-deck ovens.

● Steam Injection System

For baking breads, especially crusty varieties like baguettes, a steam system is essential to develop proper crust and volume. Look for ovens that include built-in steam injection or can be customized with one.

● Energy Efficiency

Energy consumption is a major factor in long-term operational cost. Choose ovens with insulated chambers, efficient heat circulation, and programmable features to reduce energy waste. Bakesphere ovens are designed with performance and efficiency in mind to help you control utility costs.

● Ease of Cleaning and Maintenance

Daily cleaning and regular maintenance are part of bakery life. Ovens with smooth internal surfaces, removable racks, and user-friendly interfaces simplify this task and reduce downtime. Electric ovens typically require less maintenance than gas models.

● Construction and Durability

Look for heavy-duty stainless steel construction and quality components, especially if the oven will run continuously. Bakesphere ovens are built in-house with industrial-grade materials to ensure long service life under demanding conditions.

● Automation and Production Line Compatibility

If your bakery uses or plans to adopt a machinery production system, ensure the oven can be integrated smoothly. Then you need find a reliable supplier who supports custom designs to match your automatic tray loading systems, conveyor belts, or timing controllers for seamless operation.

By weighing these considerations carefully, you can select an oven that not only meets your current needs but also supports future growth and improved workflow. In the next section, we’ll match oven types to common bakery business models to make your decision even easier.

6. Matching the Oven to Your Bakery Type

Every bakery has its own identity — from a cozy pastry shop to a large-scale food plant. To choose the right oven, it's important to match its functionality to your specific production goals, baking style, and business model. Here’s a quick guide to help you find the best fit:

● Artisan Bakery

Recommended Oven: Deck Oven

Artisan bakeries focus on handcrafted breads, baguettes, and specialty loaves. A deck oven is ideal thanks to its stone or metal decks, precise temperature zones, and steam injection. It delivers the crust, texture, and baking control needed for artisan-quality results.

● Café or Pastry Shop

Recommended Oven: Convection Oven

For cafés and patisseries producing cookies, cakes, croissants, and small pastries, a convection oven is the most efficient solution. Its fast and even baking ensures consistent results, while its compact size saves space in smaller kitchens.

● Commercial Bread Bakery / Food Factory

Recommended Oven: Rotary Rack Oven

Large bakeries and food plants require speed, volume, and reliability. The rotary rack oven meets these demands by baking dozens of trays at once with consistent results. It’s perfect for sandwich loaves, hamburger buns, muffins, and other mass-produced goods. Bakesphere rotary oven manufactuer in China provides 16/32/64 trays capacity options and light customization.

● Pizza Shop or Fast-Food Kitchen

Recommended Oven: Pizza Oven or Deck Oven (High Temp)

For restaurants and takeout chains focusing on pizza, a specialized pizza oven delivers high heat and rapid baking, essential for achieving crispy crusts and perfectly cooked toppings. A high-temperature deck oven can also work well for pan or Neapolitan-style pizzas.

● OEM/ODM Production Facilities

Recommended Solution: Customized Oven System

For industrial clients or machinery-integrated baking systems, we recommend customized ovens tailored to unique layouts, automation requirements, and specific baking trays or processes. You have to find an expertise oven manufactruer who allows to build ovens that align with your machinery production lines and efficiency targets.

7. Why Choose Bakesphere Ovens

When it comes to equipping your bakery with reliable, high-performance ovens, Bakesphere commercial baking oven factory in China stands out as a trusted partner in the commercial baking industry. Backed by our own manufacturing facility and nearly 20 years of industry expertise, we offer a full range of bakery ovens tailored to meet the demands of professional bakeries, food factories, and custom production lines.

✅ Factory-Direct Manufacturing

Bakesphere designs and builds all ovens in-house, ensuring full control over quality, materials, and precision assembly. This allows us to offer not only competitive pricing but also flexible customization options based on your unique requirements, production flow, or special tray sizes.

✅ Comprehensive Product Range

From rotary ovens and deck ovens to convection and pizza ovens, Bakesphere covers a wide spectrum of baking needs. Whether you're a local bakery or a high-output food processing facility, you’ll find an oven engineered for your specific requirements.

✅ Customization for Automation

Many modern bakeries require integration with machinery production systems. Bakesphere offers ODM & OEM services, adapting oven designs for tray auto-loading, steam systems, temperature zoning, and digital control to match your line.

✅ Durability and Baking Performance

Our ovens are built with industrial-grade stainless steel, advanced insulation, and smart heat circulation systems. This means consistent baking results, better energy efficiency, and longer service life — even under heavy daily use.

✅ Reliable Support and Service

From pre-sale consultation to after-sale technical guidance, Bakesphere offers end-to-end support. Our team works closely with clients to deliver baking solutions that meet both operational needs and long-term growth goals.

Choosing Bakesphere bakery machine supplier in China means choosing quality, innovation, and a manufacturer who understands the unique challenges of commercial baking. In the final section, we’ll wrap up with key takeaways to guide you in selecting your ideal commercial oven.

8. Conclusion: Find the Oven That Fits Your Bakery Best

Investing in the right commercial oven is a decision that impacts every aspect of your bakery — from product quality and production speed to energy efficiency and long-term profitability. Whether you’re baking artisan loaves in small batches or running a high-capacity food production line, understanding your baking needs and aligning them with the right oven type is the first step toward success.

At Bakesphere, we don’t just sell ovens — we supply solutions. With a comprehensive range of rotary, deck, convection, and pizza ovens, along with full customization and factory-direct support, we’re here to help you choose the perfect fit for your kitchen or production facility.

If you're ready to upgrade your baking equipment or need guidance on matching ovens to your production system, contact Bakesphere for a professional consultation. Let us help you turn your baking vision into reality — with efficiency, consistency, and confidence.