Top Features to Look for in a Commercial Conveyor Pizza Oven

Content

- 1.Variable Speed Controls

- 2.Adjustable Temperature Zones

- 3.Belt Width and Length

- 4.Stackable Options

- 5.Energy Efficiency

- 6.Conclusion

In the fast-paced environment of a commercial kitchen, consistency, speed, and reliability are everything—especially when it comes to baking pizzas. For high-volume pizzerias, quick-service restaurants, and food courts, a conveyor pizza oven is often the go-to solution. Unlike traditional deck or brick ovens, conveyor ovens automate the baking process, ensuring every pizza is cooked uniformly and efficiently with minimal operator intervention.

However, not all conveyor ovens are created equal. Choosing the right one involves more than just picking a size—it’s about understanding the features that directly impact performance, energy usage, and kitchen workflow. From adjustable belt speeds to stackable configurations, these features can drastically improve baking consistency, reduce cooking time, and enhance overall productivity. In this article, we’ll walk through the top features to consider when selecting a commercial conveyor pizza oven to help you make the best investment for your operation.

1. Variable Speed Controls

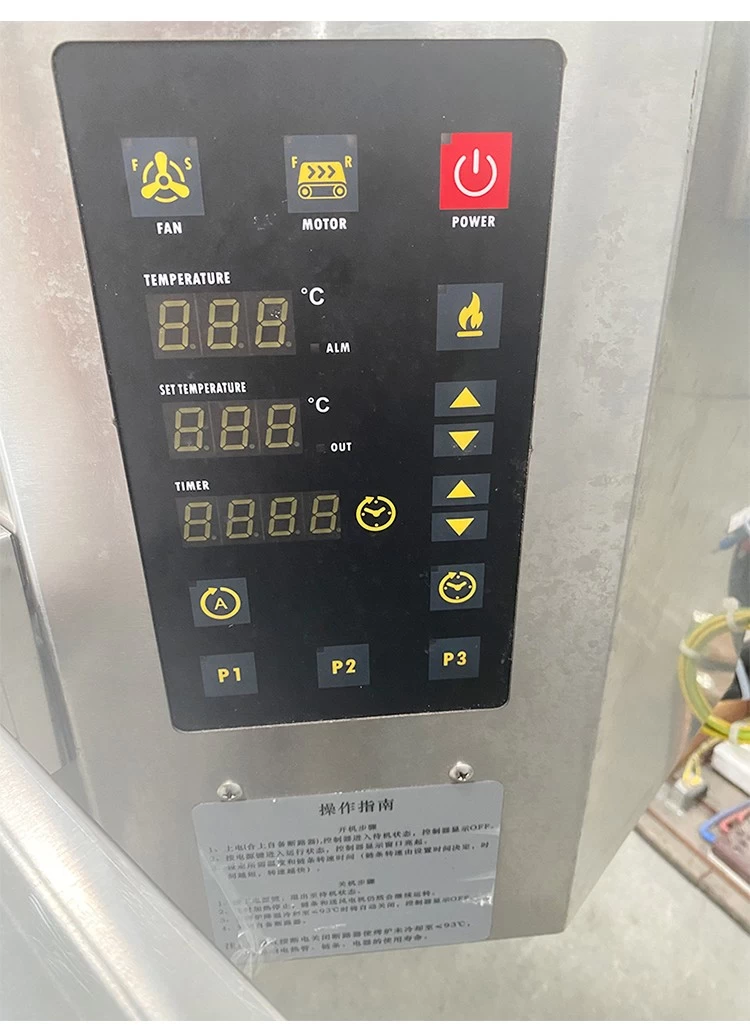

One of the most critical features in a commercial conveyor pizza oven is variable speed control. This function allows operators to adjust the speed at which the conveyor belt moves, directly influencing the amount of time a pizza spends inside the baking chamber.

Why is this important? Different types of pizzas require different cooking durations to achieve the perfect bake. A thin-crust pizza, for example, cooks quickly and benefits from a faster conveyor speed to prevent burning or over-drying. In contrast, a deep-dish or loaded pizza needs a slower belt speed to ensure thorough cooking without leaving the center underdone.

Benefits of Variable Speed Controls:

● Precise control over baking time for different pizza styles and dough thicknesses.

● Improved consistency and quality across high volumes of pizza.

● Operational flexibility to bake a variety of items—including calzones, flatbreads, and sandwiches—on the same machine.

● Reduced risk of product waste due to undercooked or overcooked pizzas.

Many modern conveyor ovens are equipped with intuitive digital interfaces that make adjusting belt speed quick and user-friendly. For example, ovens with programmable settings allow staff to pre-set speeds for specific menu items, streamlining operations during peak service hours.

Whether you’re running a fast-casual pizza chain or a high-volume commissary, variable speed control is essential for delivering consistent results without sacrificing efficiency.

2. Adjustable Temperature Zones

Modern conveyor pizza ovens often come equipped with adjustable temperature zones, allowing operators to set different heat levels across various sections of the oven—typically the front, middle, and rear. This feature enables more precise control over the baking process by accommodating the natural heat variations that occur as food travels through the oven chamber.

Why is this important? In a busy kitchen, not every pizza is the same. Some may be heavily topped with vegetables or meats, while others have light toppings or thin crusts. With adjustable temperature zones, you can tailor the heat distribution so that every part of the pizza—crust, sauce, cheese, and toppings—cooks evenly. It’s particularly useful when baking multiple types of products back-to-back, such as a thin-crust margherita followed by a deep-dish meat lover's pizza or even a stuffed calzone.

Benefits of Adjustable Temperature Zones:

● Even cooking from start to finish, regardless of topping load or crust thickness.

● Custom heat profiles for different menu items, reducing the need for manual intervention.

● Greater versatility in using the oven for items beyond pizza, such as garlic bread, pastries, or desserts.

● Improved product quality and consistency, especially for high-volume production.

Some well-known commercial oven manufacturers offer advanced models with independently controlled heating zones. These allow operators to fine-tune both top and bottom heat across different sections of the oven, enhancing flexibility and baking precision. For growing pizza chains or kitchens with diverse menus, this feature can significantly streamline production while maintaining high product standards. Bakesphere is a leading pizza baking oven manufacturer in China who has so many successful customization cases all oven the world. Contact Bakeshere to learn more details.

3. Belt Width and Length

When choosing a commercial conveyor pizza oven, belt width and length are key factors that directly affect your kitchen’s output capacity and floor plan. The belt is the platform that carries pizzas through the oven chamber, and its size determines how many items can be baked at once, as well as how long each stays under the heat.

Why Belt Size Matters

A wider belt means you can bake more pizzas side-by-side, making it ideal for high-volume operations such as pizza chains, commissary kitchens, or busy food courts. Conversely, a narrower belt is often more space-efficient and better suited to compact kitchens or specialty pizza shops where volume is lower but consistency is still crucial.

Belt length influences how long a product remains inside the oven. A longer belt allows for extended cook times—perfect for thick-crust pizzas, deep-dish styles, or pizzas with heavy toppings. Shorter belts, on the other hand, are more efficient for quick-baking thin crusts or frozen pizzas with minimal prep time.

Benefits of Choosing the Right Belt Size:

● Customizable throughput to match your business’s pizza output needs.

● Improved kitchen layout by aligning oven size with available floor space.

● Efficient workflow, minimizing bottlenecks during peak service hours.

● Flexibility to bake other items like garlic knots, flatbreads, or appetizers.

How to Choose:

Assess your hourly baking volume: For example, if you plan to bake 50–100 pizzas per hour, a 32" to 36" belt may be appropriate. Higher volumes may require wider belts or stackable units.

Consider menu variety and cooking time: Longer belts suit thicker or gourmet pizzas that need more time in the oven, while shorter belts support fast turnover for thin crusts and standard recipes.

By selecting the right combination of belt width and length, you ensure that your oven not only fits your space but also supports the level of efficiency your business demands.

4. Stackable Options

A key feature to consider when selecting a commercial conveyor pizza oven is whether the unit is stackable. Stackable conveyor ovens are designed to be installed vertically—one on top of another—allowing kitchens to increase baking capacity without expanding their footprint.

Why Stackability Matters

In busy commercial kitchens where space is often limited, the ability to stack ovens offers a smart solution for maximizing output. Instead of spreading equipment horizontally and using up valuable prep or walk space, stackable ovens help optimize vertical space, making them ideal for high-volume pizzerias, ghost kitchens, and quick-service restaurants.

Benefits of Stackable Conveyor Ovens:

● Higher production capacity without the need for additional floor space.

● Scalable design allows businesses to start with one deck and add more as demand increases.

● Operational flexibility—you can run one oven during off-peak hours and activate both or all decks during busy times.

● Consistent baking performance across all levels, with independent controls for each oven deck.

Many well-known commercial brands offer stackable conveyor oven models, often available in double or triple-stack configurations. This makes them particularly attractive for pizza chains, delivery-focused outlets, and franchises that want to scale up production without undergoing a full kitchen remodel.

Whether you're outfitting a new location or upgrading an existing kitchen, stackable conveyor ovens provide a future-ready solution that grows with your business.

5. Energy Efficiency

In today’s commercial kitchen environment, energy efficiency is more than just a bonus—it’s a strategic advantage. Energy-efficient conveyor pizza ovens are engineered to minimize power or gas consumption while still delivering consistent, high-performance baking results.

Why Energy Efficiency Matters

With ovens often running for long hours, especially in high-volume operations, energy costs can quickly add up. Choosing an energy-efficient oven not only reduces operational expenses but also helps businesses meet sustainability goals, a growing concern for many modern foodservice brands and environmentally conscious consumers.

Benefits of Energy-Efficient Conveyor Ovens:

● Lower utility bills over time, improving overall profit margins.

● Reduced carbon footprint, supporting eco-friendly kitchen practices.

● Improved temperature control, which also contributes to better product consistency and fewer cooking errors.

● Compliance with energy regulations in some regions or eligibility for energy-saving incentives and rebates.

Many leading manufacturers now integrate smart energy-saving technologies into their conveyor ovens. For example:

● Energy management systems: reduce power use during idle times.

● Fast start-up times and advanced airflow technology: enhance efficiency without compromising bake quality.

● Insulated baking chambers and cool-touch exteriors: help retain heat and reduce energy waste.

For businesses looking to lower operating costs while maintaining top-tier baking performance, energy-efficient conveyor ovens from Bakesphere conveyor pizza oven supplier in China are a wise long-term investment.

6. Conclusion

Choosing the right commercial conveyor pizza oven is a crucial decision that can significantly impact the efficiency, consistency, and profitability of your kitchen. Key features such as variable speed controls, adjustable temperature zones, belt width and length, stackable configurations, and energy efficiency are not just technical specs—they are practical tools that help you optimize performance, adapt to diverse menu offerings, and manage operational costs.

When selecting a conveyor oven, consider your production volume, available kitchen space, and menu requirements. For high-output operations, wider belts and stackable units may be essential. If you're focused on lowering energy bills or aligning with sustainability goals, prioritize models with advanced heat retention and smart energy-saving features.

Ultimately, the best oven for your business is one that aligns with your current needs while offering the flexibility to grow with your operation. Investing in the pizza ovens from Bakesphere bakery machine factory in China now sets the foundation for long-term success in a competitive foodservice market.